How to Specify Tree Grates

In this article (and downloadable PDF checklist), we walk you through the process of specifying tree grates.

Having answers to the following nine questions will ensure you get the right grate(s) and achieve the best possible outcome for your project. It also makes the quoting process faster and more accurate, keeping your budgetary goals and timelines on track.

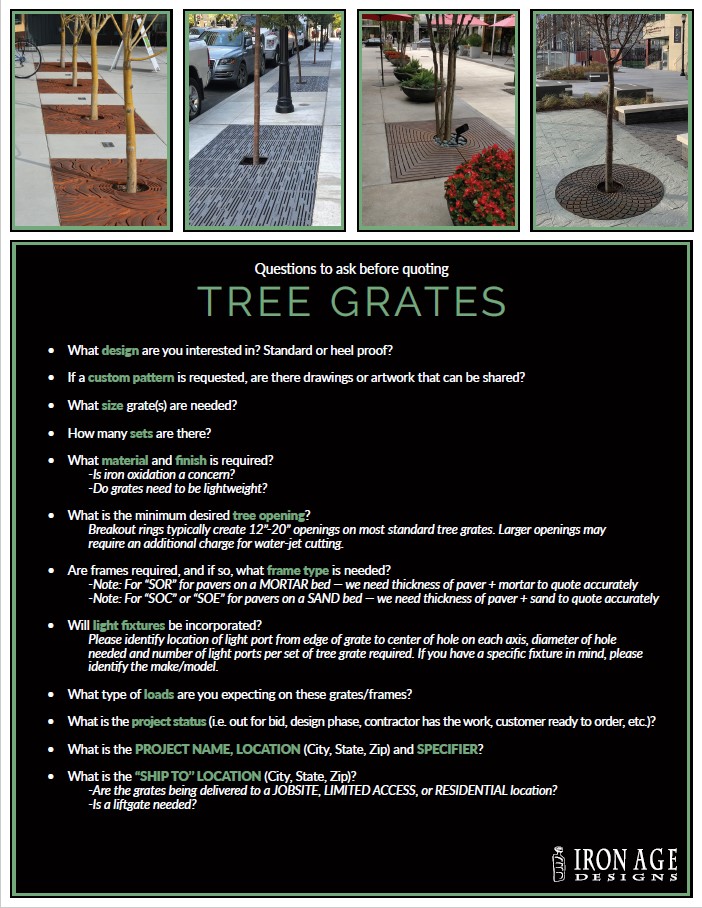

Question #1: What design are you interested in?

We have more than 20 standard tree grate designs and the ability to create completely custom patterns. So, no matter the look you are going for, we’ve got you covered.

We don’t have every size for every design, but some of our longest-running patterns are available in a wide variety of standard dimensions.

What if you go to our website and see a design you’re interested in, but we don’t have the size you need? You might want to explore getting a custom pattern made. We’ll cover that process later in the article.

Question #2: Compliance — ADA vs. heel proof?

All our grates are ADA compliant, which means they have openings no larger than ½”. A good way to think about it is if you were able to take a ½” ball bearing and roll it over the entire surface of a grate, it would never fall through.

ADA guidelines also call for accessible floor and ground surfaces that are stable, firm, and slip resistant. Our raw, cast metal grates exceed these criteria in both wet and dry conditions.

So that they don’t become a trip hazard, ADA-compliant grates can also only have a ¼” max vertical rise (or a ½” max if the rise-to-run ratio is 1:2).

ADA Compliant vs. Heel Proof — What is the Difference?

Grates designated as “heel proof” are also ADA compliant, the only difference being that heel proof grates have even smaller max openings of only ¼”.

Question #3: If a custom pattern is requested, are there drawings or artwork that can be shared?

Drawings are key. The better idea you have of exactly what type of custom casting you need, the more precise our quote can be. Initial estimates will be high if you tell us you want something custom but can’t provide much in the way of project details.

Curious about how much a custom pattern costs?

When only a small number of grates are needed, the pattern charge can run thousands of dollars. If you’re specifying a streetscape full of tree grates, we will most likely waive part or all of the pattern charge—it depends on the volume ordered. Keep that in mind when considering whether a custom pattern makes sense for your project or not.

Question #4: What size grate(s) are needed?

Our website features a product filter that sorts our tree grates by design and by size. The filter enables you to narrow your selection quickly and easily by whichever element is most important to you.

Question #5: What material and finish are required?

Our first rule of thumb, no matter the material, is to try to go with a raw finish. That way there’s nothing to wear off and nothing to maintain. With that said, you need to be aware of how raw metals will react to a given atmospheric or aquatic environment and choose appropriately for your project.

So, let’s talk about the different materials we use and the reasons for specifying each one. We’ll start with the most popular option.

Cast Iron

Extremely durable and low maintenance, cast iron is also the most affordable of the three metals we will be going over in this article.

A raw cast iron grate starts out grey in color (below, top photo). When it gets wet, the iron casting starts going through an oxidation phase (below, middle photo). It looks rusty for anywhere from a few months to a year, depending on how much foot traffic and weather it gets. You eventually end up with a dark brown patina, like any manhole cover in the street (below, bottom photo).

Arizona cast iron tree grates shown newly installed (top), 1 month after installation (middle), and a year after installation (bottom).

What If You Don’t Want Orange Grates, Even Temporarily?

If you don’t like the look of rusty grates, keep in mind that we offer a natural finish that mimics the look of aged iron that we call our Baked-On-Oil Finish.

We start out with a raw cast iron grate, get it nice and rusty, dip it in recycled vegetable oil, and bake it. The natural oxidation process is still happening underneath the surface, but this finish (see photo below) hides it while the grate transitions gracefully to its final patina.

Cast Bronze

Substantially more expensive than iron, bronze is very rarely used for castings as large as tree grates. However, if the grates are placed near circulating water systems, such as the fountain shown below, cast bronze is the preferred choice because it does not rust.

In terms of how it ages, bronze starts off bright gold and ends up anywhere from a dark brown (sometimes with burnished highpoints) to a verdigris color. The variation depends on the environment where bronze castings are placed.

Kelp 6’ Dia. tree grate in cast bronze. Shown newly installed (top) and 2 months after installation (bottom).

Cast Aluminum

Cast aluminum is a nice material if you’re working with a cooler color vocabulary and want the look of stainless steel. Aluminum does not really change color much over time and is generally priced somewhere between bronze and iron.

Do your tree grates need to be lightweight?

Castings made from aluminum 356 alloy have great strength when heat treated to T6, but are very lightweight—an important consideration for grates that are oversized or that need to be moved periodically after installation.

You can find more detailed explanations of each material and our available finishes in the Resources section of our website. If in doubt, we encourage you to contact us directly and we can help ensure you are choosing the right material and finish for your project.

Question #6: What is the minimum desired tree opening?

Whether it is visually apparent or not, all Iron Age tree grates have allocations for breaking out to a larger center opening.

Tree grates with breakout rings:

Center openings for our tree grates with breakout rings range from 12”- 20”, which is industry standard. Breakout rings offer an easy way to protect the health of urban trees by accommodating their trunk growth over time. For step-by-step instructions on how to cut breakout rings on-site, check out our video (below).

With very few exceptions, standard center openings for our other tree grates range from 12” – 24”. The breakout areas are less obvious, but the center openings of these types of grates are still designed to expand with the growth of the tree and can also be cut on-site.

Keep in mind that larger openings can be specified before installation but may require an additional charge for waterjet cutting.

Cast aluminum Spin tree grate with standard 12” opening (top), and larger opening specified before installation (bottom).

Question #7: Are frames required, and if so, what frame type is needed?

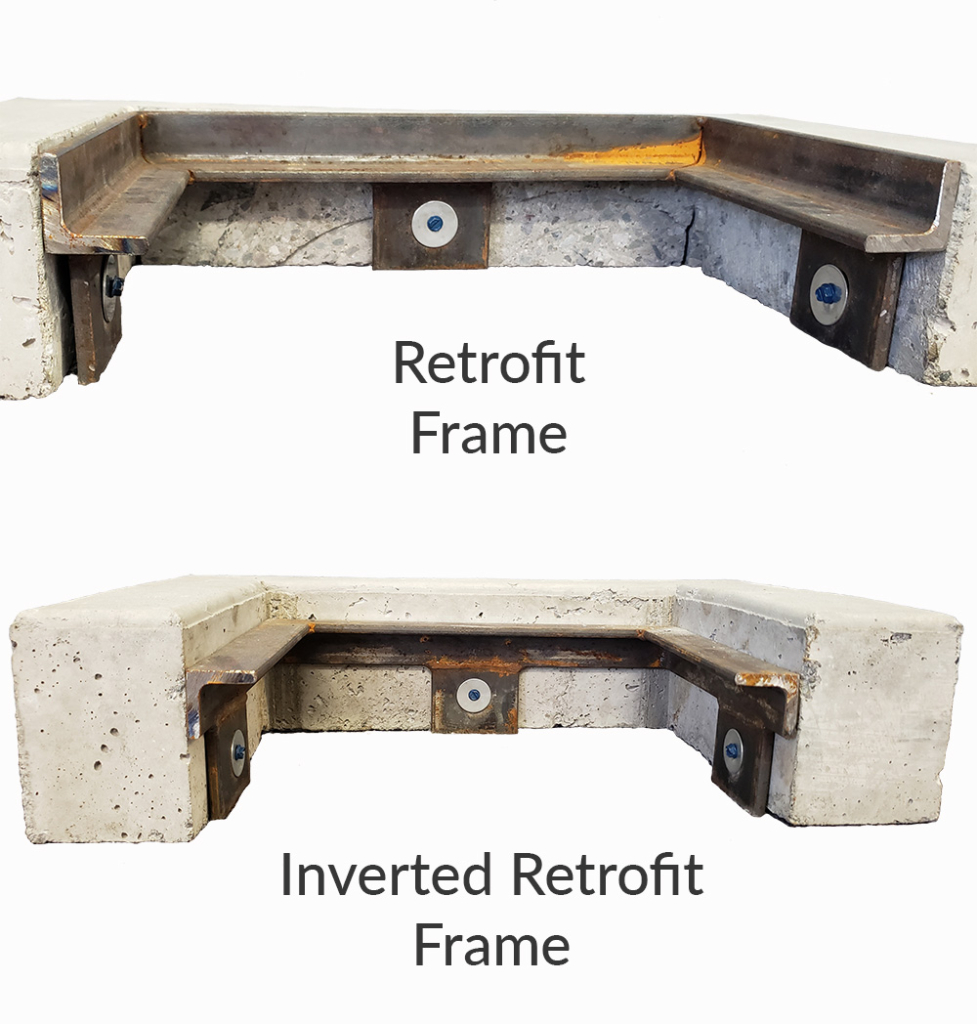

Made from angle bar and bolted or “wet set” into the top edge of the surrounding surface, frames act as a bearing shelf and stable fastening point for the grate. Steel frames also keep iron grates from directly touching the surrounding surface, helping mitigate rust staining.

Iron Age frames are all made-to-order and can accommodate many types of installation scenarios. Mounting options include embedment into new concrete, bolting to existing concrete, use with pavers, and more.

Frame Types:

“Embedment” (E frame), which has rebar attached for installation in new concrete.

“Retrofit” (R) and “Inverted Retrofit” (IR) frames, which are designed to be used with existing slabs.

“Stand Off” frames, which are used with a variety of paver options on both sand and mortar.

The overall height of a Stand-Off frame is determined by the combined thickness of the paver plus the sand or mortar, so we will need that information upfront to provide the most accurate quote.

Before we wrap up this question about frames, we also wanted to highlight the fact that Iron Age is the only manufacturer whose tree grates bolt down to their frames AS A STANDARD instead of including it as an extra cost.

Question #8: Will light fixtures be incorporated?

If there is a small number of tree grates you want to incorporate light fixtures into, the easiest and least expensive way to do that is to waterjet cut the hole.

For larger quantities, we can make allocations in the tree grate pattern, creating custom-cast holes with an integral lip that supports the light fixture. Casting the hole is more expensive than waterjet cutting, but often it’s a superior solution as it prevents the possibility of the light fixture dropping down below the level of the tree grate.

Regardless of which method you choose, we will need the following information to provide the most accurate quote:

- The location of each light port from the edge of the grate to the center of the hole on each axis

- The diameter of the hole

- The number of light ports per set of tree grates

- The make/model of the light fixture (if you have a particular one in mind)

Question #9: What type of loads are you expecting?

As a rule, tree grates are made to be pedestrian-load only but can generally handle the occasional errant vehicle hopping the curb. While not a guarantee against breakage, it’s a good-faith design effort by manufacturers to cover the most common tree grate load requirements.

If you need your tree grate(s) to withstand higher loads than the scenario outlined above, provide us with information about the real-life traffic you are anticipating the grates/frames to handle. We can help you determine not only the right load rating but also the most cost-effective way to achieve it, ensuring the product won’t fail over time.

That’s it—we’ve covered all nine questions. If you would like a condensed checklist of this content, click here for a downloadable pdf.

We hope this information was helpful. Please let us know if you have any questions, need a quote, or have a project you’d like to discuss. We look forward to hearing from you!