-

How do I know which material to specify?

Cast iron is extremely durable, low maintenance and definitely the most affordable option. A drawback for some is the “rusty” phase it goes through when first installed, but there are ways to sidestep that process if desired. (For more information, see “Cast Iron Oxidation” and “Baked-On-Oil Finish” below.)

Cast bronze is also very strong and durable and is the preferred choice for use near salt water or fountains. It does not rust, but is substantially more expensive than iron.

Cast aluminum is often requested if the look of stainless steel is desired, or if the project requires a lighter weight casting. Aluminum weathers to a dull pewter and is generally priced somewhere between bronze and iron.

For more detailed explanations of each material, see below, or contact us. We can help you determine the best material for your project.

-

CAST IRON OXIDATION — a.k.a. "RUST"

Our Locust cast iron trench grates 2 weeks after installation (l) and 2 years after installation (r).

Why are my grates turning orange?

Raw cast iron starts out grey in color, but upon contact with water, a bright orange oxide develops. This loosely adhering layer (more commonly known as “rust”) easily washes or wears away, leaving behind a more tightly adhering oxide coating that actually protects the grate from further corrosion. What you end up with is a rich, chocolate brown patina, similar to any manhole cover in the street.How long will my grates be orange?

Depending on the environment the grates are placed in, the oxidation process generally lasts anywhere from a few months to a year. Just keep in mind that the more traffic and weather the grates receive, the faster their transformation.Will the grates rust away to nothing?

Cast iron has been used for hundreds of years in the manufacture of items that need to be exceptionally durable and resistant to corrosion. For example, the Navy has traditionally made ship anchors out of cast iron. Our grates, just like those anchors, will last for decades in a raw state.What can I do if I don’t want orange grates—even temporarily?

We generally recommend letting our grates age naturally, but for those who wish to bypass the bright orange oxidation phase of raw iron, we offer an eco-friendly “Baked-On-Oil Finish” using recycled vegetable oil. For more information, see “FINISH — BAKED-ON-OIL” below.Will rust stain the area surrounding the grates?

Rust should not stain the surrounding area if your grates are installed in a pre-formed drain body or in Iron Age custom frames. The drain bodies have plastic, metallic or polymer edges and our frames have steel edges—all of which prevent the iron grates from directly touching the surrounding surface. Therefore, as long as the drain is working properly, any rust particles will flow down the drain with the water.Is rust a problem when using cast iron grates around a pool ?

Rust is not a problem as long as the grates are installed in a pre-formed drain body or custom steel frames and not touching the surrounding surfaces. Cast iron actually handles the pH balance in chlorinated pool water better than cast aluminum, which over time will turn to mush. -

We use two different types of iron for our castings — Grey Iron and Ductile Iron.

GREY IRON, ASTM Class 25, 30, 35b

This is the most widely used iron on the planet, and what we make the majority of our larger catch basin and tree grates from. Grey Iron is the most cost-effective option in terms of both strength and density, however it is too brittle to be used in thinner castings.DUCTILE IRON, ASTM A53 6 Grade 65-45-12

Ductile Iron is Grey Iron with the addition of magnesium to the alloy. Adding magnesium causes the graphite to occur as spheroids rather than as individual flakes, giving Ductile Iron a much higher strength-to-weight ratio. The spherical graphite makes Ductile Iron more pliant and less brittle, giving it the ability to be cast in very thin sections without much risk of breakage.How do I know which iron to specify?

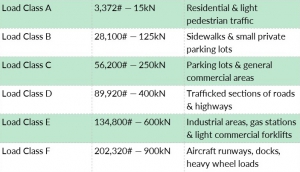

Specify the load needed—not the alloy. -

Bronze is very strong and durable, and lends itself well to the casting process. Bronze alloys are best for use near salt water or fountains. These alloys are very high in copper content, so they will weather much like copper over time.

In some areas of the world, the atmosphere itself will turn bronze alloys verdigris, especially if there is little to no foot traffic on them. When there is a fair amount of foot traffic, bronze will take on a highly burnished look. The bronze alloy (either nickel or silicon) will determine the color of the burnished highlight:

SILICON BRONZE, Alloy C87500

Gold in color when raw, before oxidation. Will age much like raw copper over time. The majority of our Bronze casting is done in Silicon Bronze.NICKEL BRONZE, Alloy C99700

Similar properties to Silicon Bronze, but more “white gold” in color when raw and not oxidized. Will age like raw copper over time, with lighter highlights. -

Aluminum is a good option if you want the look of stainless steel, as stainless steel does not take well to the casting methods used for this type of work. Silver in color when raw, cast aluminum oxidizes white, then weathers to a dull pewter.

Castings made from aluminum have the strength of steel, but are very lightweight—an important consideration for large grates or bollards that need to be moved periodically after installation.

Another benefit is that aluminum is highly corrosion-resistant. Different types of surface treatment such as anodizing can further improve this property. It is particularly useful for applications where protection and conservation are required, but selecting the proper alloy is very important:

Cast Aluminum — A356 Alloy

Can be heat-treated to T6 hardness, which will help attain heavy load ratings up to H-20.Cast Aluminum — 535 Alloy (“Almag”)

Can be used around pools, fountains, in salt water and other marine areas. -

Baked-On-Oil Finish is a full-immersion application for iron castings which uses recycled cooking oil as the coating material. Its primary purpose is as an aesthetic treatment to mimic an aged, raw iron product. As the natural oil finish wears off, it provides a smooth, graceful transition from installation to final patina.

Castings with this finish are dry to the touch, and have a minimum coefficient of friction equal to or greater than that of any painted or powder coated product. There are no VOC’s or harmful chemicals associated with the product or the process.

Surface Preparation — Castings:

Castings are arrayed in single, distinct layers and sprayed with water for 100% coverage and allowed to dry. This process is repeated a minimum of five times or until the castings have a uniform orange rust color throughout.Application — Oil:

The oil used is 100% recycled cooking oil, and is applied to 100% of the piece to be coated. The coating process is full immersion to ensure complete coverage.Baking Process:

The oiled castings are baked at a minimum of 430 degrees Fahrenheit for a minimum of 90 minutes, or until oil is polymerized (i.e. dry to the touch).Capture:

All excess oil from application and baking process is captured for re-use.Lead time:

Adding BOOF to your grates is a multi-step, labor-intensive process, and typically requires an additional 10-14 day lead time. -

Powder coated surfaces are more resistant to chipping, scratching, fading and wearing than other finishes, such as paint. Powder coat is applied as a dry powder with a small electrostatic charge that holds the powder to the metal. It is then baked in an oven, which causes the powder to “melt” into a smooth, consistent coating. This process creates a durable finish, but it has its limitations. We’ve come up with a few basic guidelines to help you decide whether powder coating is right for your project:

If the product is steel or iron, and being installed in the GROUND plane (i.e. tree grate, trench grate, manhole cover, plaque, etc.):

Stick with RAW metal. Painting or powder coating is not recommended because any traffic (foot or otherwise) will eventually wear away the finish, and the rust process will begin in the areas where the finish has worn off.

Also, keep in mind that most powder coat colors will lessen the slip resistance of the casting.

If the reason you want to powder coat your cast iron grates is that you don’t want to witness the rusty phase of their natural oxidation process, a better option is our Baked-On-Oil Finish (see above for details).

If the product is steel or iron and being installed in the VERTICAL plane:

POWDER COAT or galvanize* to prevent bleed. (Aluminum, Bronze and Stainless Steel can be used raw in the vertical plane, as these alloys typically will not bleed onto surrounding surfaces.) Our standard powder coat colors are from Cardinal® and Tiger Drylac®:For additional color choices, please visit http://www.cardinalpaint.com/powder/color-chart/

*We recommend a galvanized finish for steel only. It can theoretically be used on cast iron, but it can be risky aesthetically, and unlike steel, galvanizing cast iron does not add to its longevity.

If a light color powder coat is specified for cast iron:

We recommend an “E-Coat” full-immersion dip as a primer before the powder coat finish is applied. When using light powder coat colors (such as the DB 702 swatch shown above), it is critical that the cast iron or steel surface is coated completely–especially in hard-to-reach areas that aren’t always accessible with a powder coat spray gun. “E-Coating” immerses the object into a liquid, providing a more even and thorough distribution of the coating, and offering an extra layer of protection against rust bleeding.Lead time:

Adding “E-Coat” and/or powder coat to your grates typically requires an additional 10-14 day lead time.